HOME.TITLE

Product

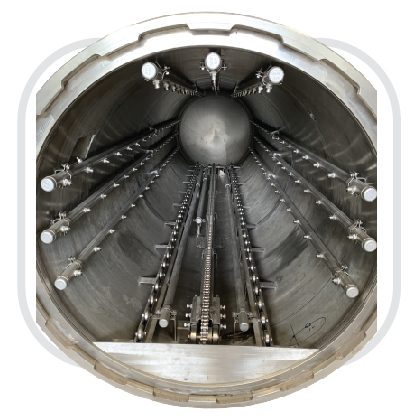

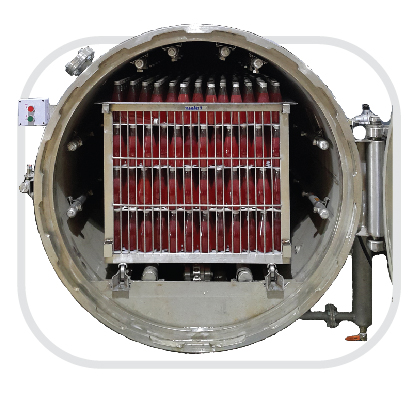

Water Spray Retort

Water Spray Retort

Water Spray Retort

Water spray retort is a steam heated water with air-overpressure. The advantage of overpressure is to protect the package integrity and prevent the package deformation. This system can be used to process with several packaging types as glass container, flexible and semi-rigid container such as retort pouch, plastic cup, tray, plastic bottle and glass container.

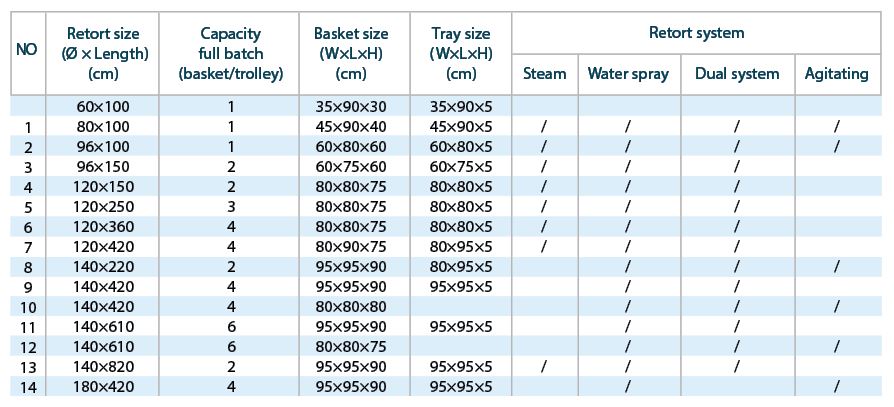

Guideline for choosing retort size and capacity

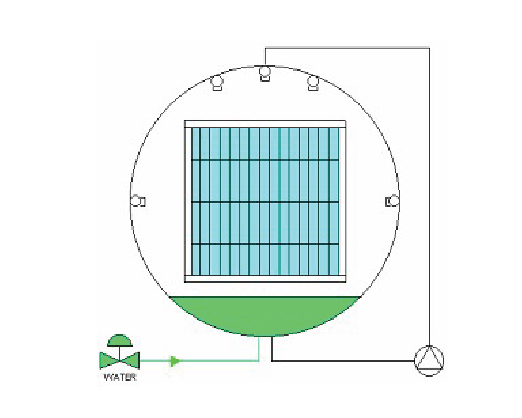

NKCP water spray system operation

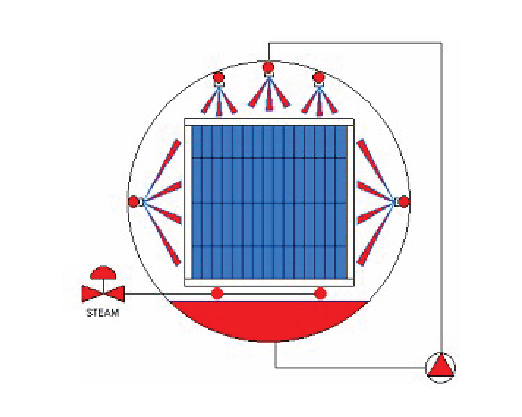

Fill water

Water is filled into retort as specified level, the water level is set to control the flow rate.

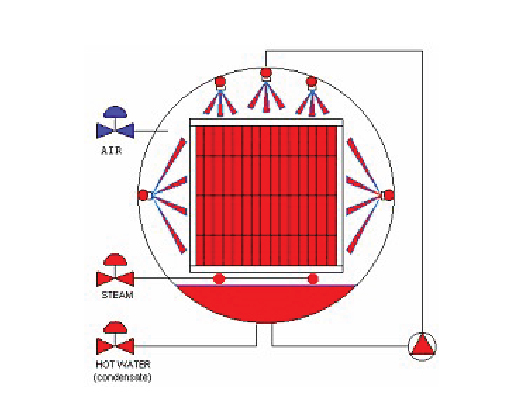

Pre-heating step

To warm water temperature to set point before circulation. The aim of preheating is to maintain IT and reduce CUT of process cycle.

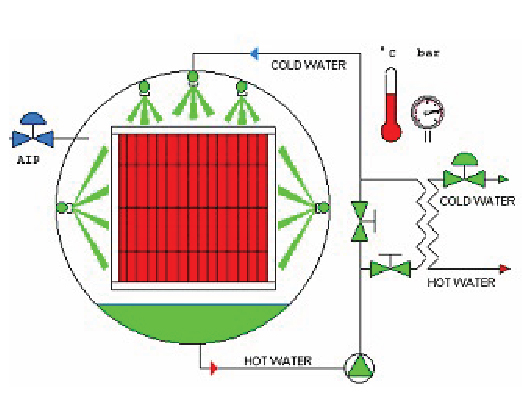

Come up period Temperature and pressure rise the target process condition and the start cooking period.

Cooking period